This page collects Hydra engineering reports as they are written. It is intended mainly for use by engineers, Hydra support scientists, and mountain support.

Hydra upgrade plan [1] (Knut Olsen, October 2005)

Hydra cable stretch [2] (Roberto De Propris, March 2009)

Pumping and Dark Current [3] (Roberto De Propris, March 2009)

Status at 2001 Jun 29

Roger Smith

(action items in yellow)

I have invested considerable effort in control of extraneous light sources. Read noise in the SITe 2Kx4K CCD in the Hydra Camera is low enough (3.4 e-) that it can easily be overwhelmed dark current, spurious charge, phosphorescence or light leaks. Recall that

Noise_Floor = SQRT{ read_noise2 + Xbin*Ybin*(Spurious_charge + Dark_Current*time) }

Read Noise (in the overscan) is 3.0 e- for the high gain setting. If the longest exposure time is half an hour, and highest binning factor is 2x2, then we require:

| Spurious_charge | << read_noise2 / (Xbin*Ybin) |

| << 3.02 / (2*2) | |

| << 2 e-/pix |

and,

| Dark_Current | << read_noise2 / (Xbin*Ybin*time) |

| << 3.02 / (2*2*0.5) | |

| << 4.5 e-/pix/hr |

(All figures below are quoted for unbinned pixels.....)

Thus...

| Noise_Floor | = SQRT{ read_noise2 + Xbin*Ybin*(Spurious_charge + Dark_Current*time) } |

| = SQRT{ 3.02 + 2 * 2 *( 0.25 + 0.7 * 0.5 ) } | |

| = 3.4 e- |

2001 August 31

Roger Smith

(action items in green)

Signal to noise in the Hydra Bench Spectrograph is often limited by the noise floor of the detector, which is critically dependent on dark current. Binned by 2 in one or both dimensions, is commonly used to improve the signal to noise ratio or the read time. One must remember that while this helps overcome electronic noise it doesn't help overcome the dark current: binning the signal also bins the dark current.

We have to concern ourselves with all sources of "unwanted signal". Noise in the absence of any astronomical signal is determined by the summation in quadrature of the noise associated with

This is the charge which accumulates per unit time as some electrons in the valence band gain enough energy to overcome the bandgap and jump up into the conduction band. As the detector is cooled the probability that a valence band electron acquires enough energy will drop so that the dark current drops exponentially with temperature. At least this is the case for electrons in a perfect silicon crystal.

In a real device there are imperfections, impurities and crystal dislocations which provide intermediate energy states so that a valence electron can get to the conduction band in two smaller energy steps, increasing the probability of a "thermally generated" conduction band electron. These "hot pixels" produce less dark current with temperature too.

The density of crystal imperfections is greatest at the interface with the oxide layer. Dark current here is suppressed by taking the electrodes negative enough to pull "holes" out of the channel stops (ion implants that create potential barriers between columns). These holes populate the surface of the CCD just under the oxide layer, while the signal charge is repelled to a layer deeper in the CCD. The holes recombine with electrons generated thermally at the surface so that they never reach the storage well.

So, dark current is controlled by lowering the CCD temperature and by maintaining all clock phases negative during integration (MPP mode). The minimum temperature reached by the CCD mount is about 160-165K depending on ambient temperature (radiant load). This should be low enough to ensure good dark current performance. However it was found that dark current always exceeded that expected for the mount temperature measured. The most likely explanation for this is that the CCD is not making good enough thermal contact with the mount and that its temperature is being increased by the radiant load. Fixing this appeared to involve building a new detector mount. Rather than do this the Nitrogen flask is evacuated to promote evaporation/boiling which continues until the remaining liquid solidifies. The temperature drops by 15 degrees in the process and reduces the dark current to an acceptably low level.

Charge injection is the leakage of charge into the image area from the periphery of the CCD during the erase cycle. It can't be erased away since it is smeared across the chip by the erase process. Instead we can clock in reverse at the end of the erase cycle to push it back towards the edge where it originates. I mention it here because it is a serious problem in some of the CCDs in Mosaic which are of the same type, though much less so in this CCD.

Spurious charge is the small amount of charge generated by clocking the CCD. The mechanism is impact ionization: the surface just under the oxide separating the electrodes from the depletion region are populated by holes (due to the negative level on the clocks). This is good since these holes recombine with dark current generated as valence band electrons are excited to conduction band more easily by hopping to the intermediate energy levels produced by interface defects. However as these holes flow back into the channel stops during the rising edges of the clocks they have a low but finite probability of delivering energy to valence electrons which once liberated are collected like signal electrons. At the clock voltages needed to achieve full well, one sees about 2 electrons of spurious charge per pixel implying the probability of generating the spurious electron is about 1 in 2000 per shift.

When high gain is sleeted in the setdetector menu, the waveform compiler embeds commands in the new waveform macro which reduces the high levels of the parallel clocks. This reduces the spurious charge to an acceptable level at the expense of full well. When the high gain setting is selected the well capacity is reduced to 15000 e-. At 0.84e-/ADU this represents 18000 ADU, but when binned 2x2 exceeds the ADC range by about 10% so the loss in well capacity will often not be noticed.

Obviously light leaking into the spectrograph masquerades as dark current and has exactly the same effect. While light leaks are in principal very simple to understand there is an extensive set of tips in the section on Eliminating Light Leaks, which you should read if you detect a problem.

Check for light leaks (etc) before each observing block !....

It is most likely that to maintain full sensitivity of the spectrograph it will be necessary to verify that all of these "dark signals" are within normal bounds prior to each observing block. To do this take the following full frame exposures with binning set to 2x2.

If the dark signal is abnormally high, even when dome and surrounding room lights are off, check that no abnormal or unauthorized objects have been left in the room which may be phosphorescing. For example the paint on some nitrogen dewars may glow in the dark, too faintly to see by eye but enough to affect the CCD. Unless you find a simple explanation like this, don't waste time guessing about the cause: you should use a cooled CCD and camera lens to image the bench spectrograph room.

Recall that

| Noise_Floor = |

SQRT{ read_noise2 + Xbin*Ybin*(Spurious_charge + [Dark_Current + light_leak]*time) } |

Read Noise (in the overscan) is 3.0 e- for the high gain setting. Assuming that the highest binning factor is 2x2, then we require:

| Spurious_charge | << read_noise2 / (Xbin*Ybin) |

| << 3.02 / (2*2) | |

| << 2 e-/unbinned_pixel |

and if the longest exposure time is half and hour, then we require:

|

Dark_Current + Light_leaks |

<< read_noise2 / (Xbin*Ybin*time) |

| << 3.02 / (2*2*0.5) | |

| << 4.5 e-/unbinned_pixel/hour |

When all is working correctly,

| Noise_Floor | = SQRT{ read_noise2 + Xbin*Ybin*(Spurious_charge + Dark_Current*time) } |

| = SQRT{ 3.02 + 2 * 2 *( 0.25 + 0.7 * 0.5 ) } | |

| = 3.4 e- |

This has not been as simple as one might think! Here are some tips....

Many materials absorb light then re-emit it over a long period of time. This can cause a dark current which decays over time and is thus harder to pin down. It is therefore important to not leave any item inside the room unless it is essential and has been proven to be free from phosphorescence. These are some examples which have been addressed:

If no obvious source is found after consulting the above checklists, don't waste time guessing. Use a cooled CCD camera fitted with a camera lens and integrating for 2-5 minutes to identify light sources. The following setup is very effective:

Sometimes it can be difficult to figure out exactly what you are looking at in the noisy dark images. In this case it helps to take a short exposure without moving the camera leaving a low light source on in the room. Use the smallest aperture and low light such as leaving the door open into the anteroom. Be careful not to be confused by reflections from the metallic surfaces or by the light emitted by the arcon you are using. Its data fibers need to be taped over and it needs to be wrapped in black cloth. To avoid spending all day in the elevator, get an assistant at the keyboard downstairs or setup a laptop on the network to provide a local terminal for controlling Arcon.

The following notes were made during commissioning

and are left here for completeness

though some of the information is duplicated.

November 2001

Knut Olsen, on behalf of the people who work on Hydra: Rolando Cantarutti, Rodolfo Cardemil, Manuel Martinez, Daniel Maturana, Andres Montane, Javier Rojas, Oscar Saa, Nick Suntzeff, Ricardo Venegas

The Hydra spectrograph and positioner have had a history of problems since its commissioning. In the months July-September 2001, good progress was made towards fixing the worst problems. Below are summaries of the problems we have encountered and the work done to fix them.

The problems with the positioner resulted in the loss of often several hours per night.

Many thanks to Sam Barden, Phil Massey, Dave Sawyer, and Bezhad Aredeshi for their advice on fixing Hydra's troubles.

Our top priority for Hydra before the October 2001 observing block was to reduce the failure rate of the gripper. Many of the problems experienced in previous runs, listed above, have now been fixed:

However, with the appearance of another problem with the gripper (#3), it became clear that a complete overhaul of the gripper was necessary. Andres Montane (hardware) and Rolando Cantarruti (software) jointly took on this work, with Ricardo Venegas supporting.

[4]

[4]

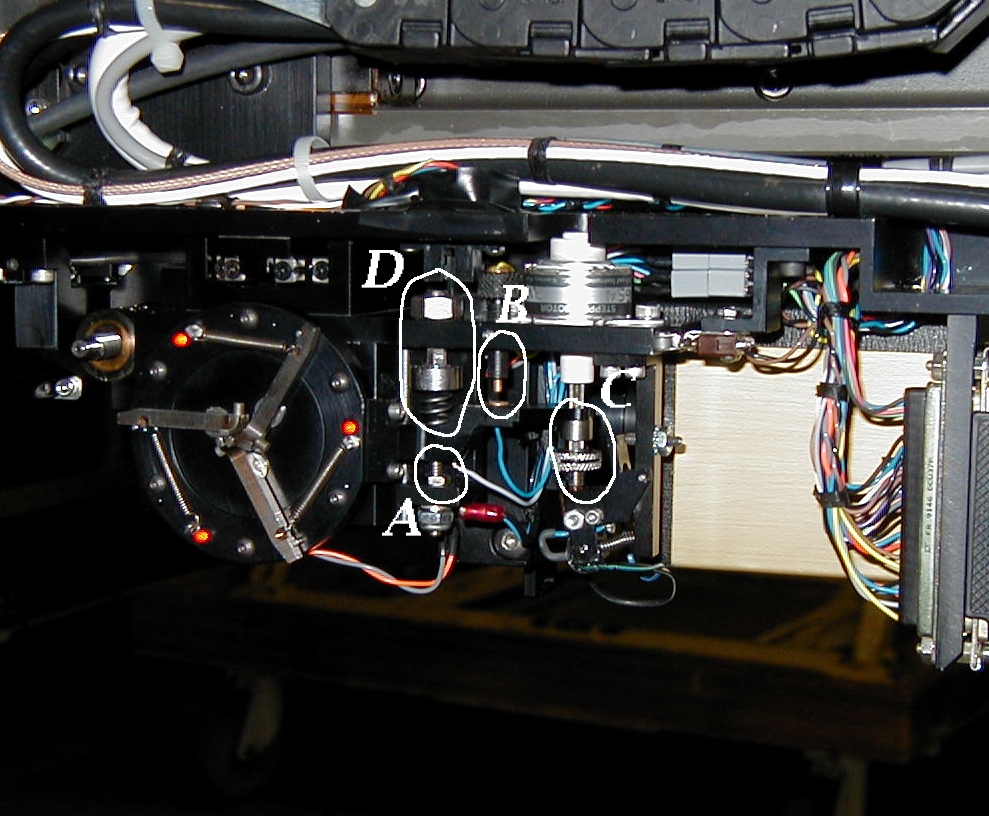

Fig. 1. Close-up of gripper assembly

In order to uncover the cause of the gripper troubles, Andres & Co. needed to understand how the gripper behaves during the sequence of picking up a button, moving it, and putting it back onto the plate. What is supposed to happen? From Sam Barden:

The gripper thus cycles through three states while placing a button: open, closed, and relaxed. (A fourth state, "open wide", is also available, but is used mainly when the gripper is initialized). How does the gripper achieve these states? In Fig. 1 above, the three teeth of the gripper are mounted on the black wheel with red LEDs attached. When this wheel rotates, the teeth tilt about their mounting pins and the jaw opens or closes. The motor which provides the power to rotate the wheel is located immediately above the label "C". "A"-"D" indicate four mechanical switches. From our observations of the gripper in April 2001 and conversation with Sam Barden, we established that:

Andres&Co. independently established these functions of the switches. Their real insight, however, came from Andres' understanding of the mechanics of the system. Andres first observed that the turning of the gripper motor compresses the spring in switch C and opens the gripper. The closing of the gripper is then entirely driven by the stored tension in the spring. Second, given the distance by which the teeth are supposed to move in order to reach the open position, Andres calculated the distance through which the motor needs to turn. He found that the motor was stopping before it reached the full open position, held back by excessive force from the spring and by a spring in switch B. After he adjusted the positions of switches B and C, the gripper was able to complete the opening of the jaws. (Incidentally, Rolando discovered that the setting of switch B is never used in the software control, so that it actually serves no purpose). Third, Andres noted that when closing the gripper with a button in the jaw, the teeth continued to rotate even after they were fully closed around the gripper. By tuning switch A, he was able to stop the closing of the jaw before the teeth imparted rotation to the button.

Following Andres', Rolando's, and Ricardo's work on the gripper, the October observing block passed with no trips to the cage to untangle problems with the fibers, and virtually zero problems with the gripper. Their work leaves us with two valuable lessons:

Andes will refine the process of tuning the gripper before the next Hydra block.

[5]

[5]

Fig. 2. Heads of arrows are current FOPS fiber positions, tails are positions before commissioning

Page in Spanish

Detector, dewar and Arcon work, Ramon Galvez H., June 2002

More detector, dewar and Arcon work - Ramon Galvez , August 16th, 2002

| CCD dwr vac before pumping | : 300 Torr |

| CCD dwr vac after pumping | : 0 mT |

| LN2 flask vac after refill | : 400 Torr |

| LN2 flask vac for solid state | : 20 Torr ( after 1hr pumping ) |

Ramon will check out the vacuum and prepare a new molecular sieve during the week of 21/3

On the next engineering night, we will measure the rotation near the equator and adjust x_offset and y_offset by going to the pole.

Rolando is looking at exactly how big the axial alignment error is.

Can Roberto check the optical alignment soon?

Rolando will add a fix to the code

First, Hernan, Ricardo, Knut, Daniel, and Patricio will write up a detailed set of procedures, hints, and tricks for doing the echelle setup

We want to investigate getting replacement ThAr lamps--Oscar will contact Kitt Peak to find out what they are using

Observer support will check out what is currently in the chimney.

Oscar and Knut will contact Kitt Peak about what lamps they have and who supplies them

Hernan, Oscar, Ricardo, Knut, Patricio will also make a web page listing all of our comparison lamp supplies

Andres and Ricardo will check out the z-limit switch and the general mechanical tuning of the gripper during the week of 21/3. Andres will also see whether a new z-limit switch design may be implemented before April 16, 2004.

The trouble with the erratic limit switch signals was solved by replacing the spare Galil with the original Galil. Trouble is that the original Galil had some problems of its own, such as getting lost and producing "x-y stage not at destination" errors. The Galil boxes have been sent back to the company twice for repair, but have been returned with the statement that there is nothing wrong with them. Gale will ask Galil for a quote on a new replacement.

FIXED after David changed the values and Rolando incorporated the fix into automated software.

Given that generally our hydraassign files successfully positioned fibers further from the pole, and without any problems at the WIYN fiber instrument in more than three hundred pointings over the last four years our experience suggests that possibly the positioning troubles find their explanation in a residual telescope polar alignment error. Mr. Bremer had remarked that the Blanco Telescope has a significant residual alignment error, as do many if not all equatorially mounted telescopes.

While Wallace's pointing model and correction software does reduce telescope pointing discrepancies, canceling the error on-axis, we wonder if the field rotation correction coefficients that Wallace\'s software produces are passed to the hydra software. Were they not read by hydra, then a three arc-minute telescope misalignment could produce major problem when hydra attempts to observe near the pole.

We would be grateful if this possibility could be looked into, possibly allowing for manual keyboard entry (or its equivalent) of the pointing model generated coefficients. In particular, we should be grateful if this might be resolved on the April 16th engineering night, so that our next observer working on this project April 17th through the 19th could do the fields we had to delete from our current observing program that was, in other respects, highly successful.

Hydra Status Report, Notes from the meeting April 2000 - Updates 2002, 2003

Knut Olsen, 4/3/2002

Updated 5/24/2002

Updated 7/14/2003

People and jobs assigned, in order of priority. See list below for job descriptions. Updates in light blue.

Srs:

A Matheson's Oxygen Deficiency Monitor model #8061 was installed inside the Hydra room, the sensor is close to the refilling area and the unit is in the room next to it (upper right corner). It was adjusted at 20.9% as recommended. A pulsating alarm tone sounds if the oxygen level drops below 19.5%

Effects/Symptoms:

19.5%-21.0% no symptom

14.0%-19.5% Headache, fatigue, faulty judgment

10.0%-14.0% Rise in temperature, difficulty breathing

6.0% -10.0% Convulsions, indistinct consciousness

below 6.0% Coma and heart failure, death in minutes

The unit should be used when work is done in the room, in special while refilling the dewar.

It uses 2 AA rechargable batteries (steady sound means battery low). They last ~75 hours, when fully charged.

Sensor's lifetime: 18-24 months, starting today (July 2003). Accuracy +/- 0.3%

That's all

Danmat S.A

Buenas Noticias,

Thank Manuel Martinez and Unisite (the ETS device programmer) the brand new flash eprom and the bad one from the spare galil could be programmed. The eprom in the original Galil (the only good one we had) served as master and Manuel made a backup of its content. The original Galil and the spare Galil are functioning now. I let run a largecircle and a parklarge with each eprom. No one error happened. It seems that our Galil units aren't able to program the flash eproms or I'm unable to get them burnt. I got the programs into the eproms but the burn in command produced a timeout error only.

We still have two virgin eproms. I'll send them to Manuel for programming. I think, it isn't worth to investigate, why our galil doesn't program the eproms, because the Unisite can do it better. It looks like the trouble with the hydra spares will be then over for the next time.

Saludos

Javier

Here is a quick summary of the topics discussed at the Hydra meeting on August 23, 2004, and the conclusions we reached:

There are two basic solutions. One is to buy a motor and external encoder and use the existing, now-defunct SMC connection for the shutter operation to operate the motor. May be a significant mechanical design effort, however. The second is to replace the existing manual micrometer with a motorized version. This is mechanically easy, but communication with the SMC requires study.

--> Andres, Manuel, Enrique, Javier, Ricardo, Rodolfo will study the problem

Need to ensure that the pellicle may be replaced without damage.

--> Ricardo and Andres will discuss

Several apparent z-limit switch failures even after redesign and installation by Andres.

--> Javier and Enrique will try to reproduce the problem on the next turno, and write a proposal for a solution

--> send Knut any items you can think of

The first three refer to the z-axis failures referred to above.

The next two refer to failure of the guider, the solution of which was reported in #502. But we need either spare VME cards, or perhaps Rolando's software patch.

--> Enrique and Javier wil discuss with Rolando

The last (320) refers to the broken echelle filter #6.

--> Knut will discuss finding a replacement with Roberto

Exists, but doesn't work. Why?

--> Knut will look into it.

By Charles Corson, February 2010.

There are a great number of things that can cause the linear actuator to fail. I would first decouple it from the linear actuator from the articulation arm, the straight piece which comes down from the gripper face.

This decoupling is very simple: you remove the jam nut on the end of the ball screw at the left end of the actuator. Once done, you command the gripper to open and close.

What you are looking for is a smooth, consistent in/out motion of the balls screw, the linear actuation. Without any mechanical loading, this should be a simple test of the actuator itself. If it appears to be 'sticking', you can apply a drop or two of light lubricant. I've seen these actuators fail because the original lubricant has 'gummed' up, become dry and very sticky, waxy. You also want to look closely at the linear keyway on the ball screw. You will see just at that face of the teflon nut, a teflon key, or tab, that fits directly into that slot. The Tab should be in good shape, not rounded, or deformed. If it is, the ball screw is likely turning with the motor under high load and then there is a complete loss of linear actuation. The ball screw must have no rotation in relation to the motor turns. Of course, it rotates within the nut.

Let us assume that the linear actuator is good with no mechanical load. I would then be highly suspect of the various mechanical adjustments: position of jam nut for correct 'relax' tension on the button, position of the close 'stop', position of the 'open' stop. There is no easy way to explain this fully, adequately. I've found that it is an iterative tuning so that OPEN is at the correct position, N-steps produces the correct relative position for 'relax' state, and the right position for close. To throw one more adjustment in the mix, one then has to have the 'tension' the spring force of the jam nut and spring on the linear actuator at the right state.

Here is YET ANOTHER issue to consider. There is a IC stepper driver on the controller card. Under mechanical load, if this driver is 'bad' or over-heating, the stepper will stall of course.

Don't assume all gripper failures have to do with the motor.

Links

[1] http://www.ctio.noao.edu/noao/sites/default/files/instruments/spectrographs/UpgradePlan.doc.pdf

[2] http://www.ctio.noao.edu/noao/sites/default/files/instruments/spectrographs/Fibers.pdf

[3] http://www.ctio.noao.edu/noao/sites/default/files/instruments/spectrographs/hydra_dc.pdf

[4] http://www.ctio.noao.edu/noao/sites/default/files/instruments/spectrographs/gripperlab.jpg

[5] http://www.ctio.noao.edu/noao/sites/default/files/instruments/spectrographs/fops2.gif

[6] http://www.ctio.noao.edu/noao/content/Hydra-Dark-Current-II-Keeping-dark-current-low-2001

[7] http://www.ctio.noao.edu/noao/content/peter-frinchaboy-bill-kunkels-mail

[8] http://www.ctio.noao.edu/noao/content/daniels-email

[9] http://www.ctio.noao.edu/noao/content/maintenance-work-between-observing-blocks

[10] http://www.ctio.noao.edu/noao/content/javiers-email